Vertical Farming, continued

This is page 4 of our nine page series on hydroponic vertical farming. Click any of the below pages to jump to that page.

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9

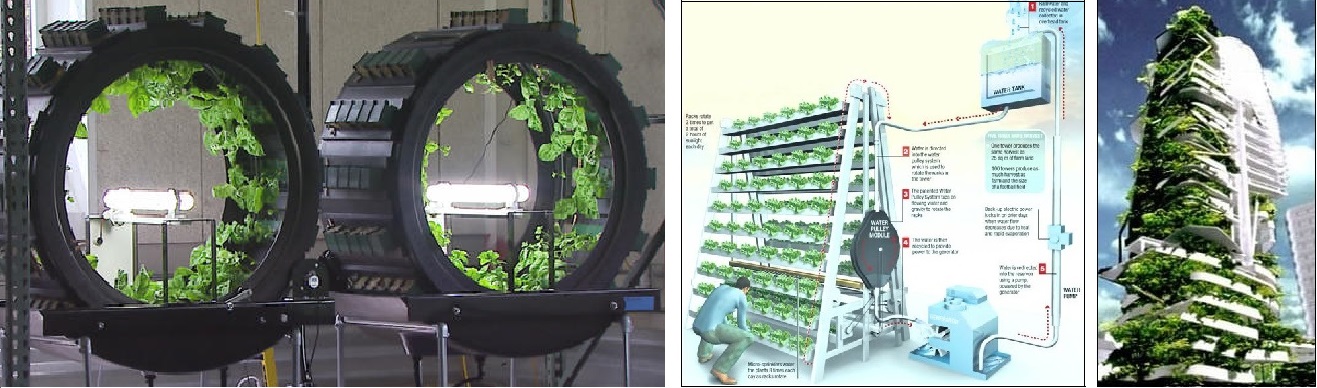

Vertical farming as a design approach spans a lot of different ideas. The image on the left is a pair of vertical rack systems with a variety of crops well along in maturity. The trays can be rotated in order to allow for convenient access to any given plant. The rotation also ensures each plant has good access to air and light. It's hard to see in the photo, but the plants are irrigated in a pool at the bottom. The middle image is different rack system along with a person for some comparative scale. Here it's easy to see how difficult the top racks would be to reach from ground level. The mechanized rack brings those upper trays down to ground level where they're easy to reach. The image on the right is an artist's rendition for a proposed building-scale vertical farming system, where each growing level coincides with another building level, so that each level is easy to reach. The plants' exposure to air and sunlight not only improves the immediate building surroundings, both inside and out. In this sense, vertical farming would live up to its potential to feed an urban population, while also providing other environmental benefits. Some celebrate the plans for such buildings as being the salvation for urban deserts. Others criticize such buildings as being absurdly costly and impractical in the very urban areas where they are proposed. Photo credits from left to right: a Powerhouse Hydroponics article about Green Spirit Farms; a PermacultureNews article on vertical farming in Singapore; and a proposed high-rise still pending construction in Singapore.

Potential for Hobbyist and Commercial Vertical Farming

In review, then, vertical farming has one massive advantage: intensive growth of plants in a minimal volume of space. The disadvantages include one or more of the following: higher labor costs, higher irrigation, power, wastewater, lighting and structural costs. A hobbyist with a small system may be able to set up a system which minimizes the disadvantages while capitalizing on the increased production. Commercial operations, however, need to really carefully examine all these costs to make sure the increased production can realistically overcome those factors.

For those readers who are interested in reading more about how the above-mentioned commercial ventures failed, check out this interview with the three CEO’s of those companies: https://urbanverticalfarmingproject.com/2017/03/04/why-vertical-farms-fail/#more-3642

For fans of vertical farming, and for those who look at vertical farming as having potential despite the failures, take heart. This approach does have promise. As we’ve already seen in other industries, sometimes a promising approach has a few major stumbles before finding its feet. Long term success is not a question of immediate success, but rather of persistence and learning from past mistakes. In that spirit, then, we’ll continue reviewing this approach and looking at what it can and cannot do. It can do a number of things well, when some necessary caveats are met.

One approach to of vertical farming which we will mention here, but which we won’t spend a lot of time on, is the popular idea that vertical farming can and possibly should be incorporated into advanced building designs. Some advocates start with the vertical farming concept, then build entire structures around that core concept. Others start with the building design, and then incorporate vertical farming in afterwards. This idea is at once a potential advantage, and/or disadvantage, depending on how its handled. One strong possibility which holds great promise is the notion that vertical farming trays will be incorporated into the building’s structure, in ways which still permit easy human access to the crops. One possibility is central stacks of growing trays, surrounded by catwalks which allow easy access to the crops without need for ladders or scissor lifts. This would eliminate many of the disadvantages listed above. However, this adds dramatically to both the cost and the complexity of any vertical farming system. The building and the business and the crops would all need to be planned simultaneously and integrated with great care. This eliminates the vertical farming approach as a viable possibility for all but the deepest pockets, which I happen to count as a strong disadvantage.

Another possibility which is considerably smaller and less complex, is the concept of revolving trays. This gets into a fair amount of mechanical complexity, and it may be more hassle than many people want to mess with. However, it very nicely eliminates the problems of trays being too high to reach. In this variation, a set of trays is mounted on a frame which includes a vertical conveyor, which can raise or lower the trays. The conveyor can be set up to either turn continuously or rotate only as needed. These tray racks can range from relatively small, only 6’ to 8’ high, all the way up to 20’ racks. For small-scale vertical farming fans, and/or for those who don’t mind a bit of mechanical complexity, this approach also nicely solves the issue of how to reach high trays without ladders or scissor lifts. Unfortunately, even this approach has some drawbacks. First, it often takes up more room than simpler, fixed racks, thanks to the conveyor mechanisms. Secondly, the system costs quite a bit more compared to fixed racks, which can price the system out of range of many small-scale growers. Third, the mechanisms for such racks introduce additional complexities to what is already a fairly involved system. Again, some growers would gratefully exchange those complexities for the increased productivity; others won’t want to mess with it. Each grower will have to decide that for him/herself.

BACK NEXT

This is page 4 of our nine page series on hydroponic vertical farming. Click any of the below pages to jump to that page.

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9